- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

General-Purpose Silicone Rubber for washer manufacturing is a versatile, high-performance material designed for producing washers and seals across multiple industries. With exceptional processing efficiency, it ensures fast extrusion speeds, impressive durability, and superior electrical insulation. Compliant with ROHS, REACH, and FDA standards, it guarantees safety for both environmental and consumer needs. Its excellent compression resistance and tear strength make it the ideal choice for long-lasting washers and industrial sealing applications.

Efficient High-Volume Production: Enables rapid extrusion, optimizing manufacturing efficiency for large-scale production.

Superior Electrical Insulation: Provides excellent electrical properties, ensuring safe, reliable performance in demanding applications.

Exceptional Durability: Resists long-term mechanical and environmental stress, making it ideal for washers and seals.

Customizable Hardness Range: Offers adjustable Shore A hardness (50-80), catering to various industrial needs.

Certified Safety Standards: Complies with ROHS, REACH, and FDA regulations, ensuring environmental and consumer safety.

Reliable Compression Resistance: Maintains shape and performance under constant pressure, crucial for sealing and gasket applications.

General-Purpose Silicone Rubber for washer manufacturing is a versatile, high-performance material designed for producing washers and seals across multiple industries. With exceptional processing efficiency, it ensures fast extrusion speeds, impressive durability, and superior electrical insulation. Compliant with ROHS, REACH, and FDA standards, it guarantees safety for both environmental and consumer needs. Its excellent compression resistance and tear strength make it the ideal choice for long-lasting washers and industrial sealing applications.

Efficient High-Volume Production: Enables rapid extrusion, optimizing manufacturing efficiency for large-scale production.

Superior Electrical Insulation: Provides excellent electrical properties, ensuring safe, reliable performance in demanding applications.

Exceptional Durability: Resists long-term mechanical and environmental stress, making it ideal for washers and seals.

Customizable Hardness Range: Offers adjustable Shore A hardness (50-80), catering to various industrial needs.

Certified Safety Standards: Complies with ROHS, REACH, and FDA regulations, ensuring environmental and consumer safety.

Reliable Compression Resistance: Maintains shape and performance under constant pressure, crucial for sealing and gasket applications.

Type Number | HF-2150J | HF-2160J | HF-2170J | HF-2180J |

Hardness (Shore A) | 50±3 | 60±3 | 70±3 | 80±3 |

Plasticity (Duro) | 180±20 | 210±20 | 280±20 | 280±20 |

Density (g/cm³) | 1.17±0.05 | 1.2±0.05 | 1.22±0.05 | 1.22±0.05 |

Tensile Strength (MPa) | ≥7.5 | ≥7.5 | ≥7.0 | ≥6.0 |

Elongation (%) | ≥400 | ≥350 | ≥250 | ≥200 |

Compression Set (%) (175°C × 22h) | ≤10 | ≤10 | ≤8 | ≤6 |

Tear Strength (kN/m) | ≥15 | ≥15 | ≥15 | ≥15 |

Rebound (%) | ≥45 | ≥40 | ≥40 | ≥35 |

Hardness: Available in Shore A hardness levels from 50 to 80, customizable for various applications.

Plasticity: Duro values range from 180 to 280, ensuring suitable flexibility for different needs.

Density: The rubber has a consistent density ranging from 1.17 to 1.22 g/cm³.

Tensile Strength: Ranges from ≥6.0 MPa to ≥7.5 MPa, providing reliable strength under stress.

Elongation: With elongation from ≥200% to ≥400%, it ensures excellent flexibility and stretchability.

Compression Set: Ranges from ≤6% to ≤10% after 175°C for 22 hours, ensuring shape retention under pressure.

Tear Strength: Offers high tear strength of ≥15 kN/m, making it durable for industrial use.

Rebound: Rebound percentages vary from ≥35% to ≥45%, indicating good resilience.

Type Number | HF-2150J | HF-2160J | HF-2170J | HF-2180J |

Hardness (Shore A) | 50±3 | 60±3 | 70±3 | 80±3 |

Plasticity (Duro) | 180±20 | 210±20 | 280±20 | 280±20 |

Density (g/cm³) | 1.17±0.05 | 1.2±0.05 | 1.22±0.05 | 1.22±0.05 |

Tensile Strength (MPa) | ≥7.5 | ≥7.5 | ≥7.0 | ≥6.0 |

Elongation (%) | ≥400 | ≥350 | ≥250 | ≥200 |

Compression Set (%) (175°C × 22h) | ≤10 | ≤10 | ≤8 | ≤6 |

Tear Strength (kN/m) | ≥15 | ≥15 | ≥15 | ≥15 |

Rebound (%) | ≥45 | ≥40 | ≥40 | ≥35 |

Hardness: Available in Shore A hardness levels from 50 to 80, customizable for various applications.

Plasticity: Duro values range from 180 to 280, ensuring suitable flexibility for different needs.

Density: The rubber has a consistent density ranging from 1.17 to 1.22 g/cm³.

Tensile Strength: Ranges from ≥6.0 MPa to ≥7.5 MPa, providing reliable strength under stress.

Elongation: With elongation from ≥200% to ≥400%, it ensures excellent flexibility and stretchability.

Compression Set: Ranges from ≤6% to ≤10% after 175°C for 22 hours, ensuring shape retention under pressure.

Tear Strength: Offers high tear strength of ≥15 kN/m, making it durable for industrial use.

Rebound: Rebound percentages vary from ≥35% to ≥45%, indicating good resilience.

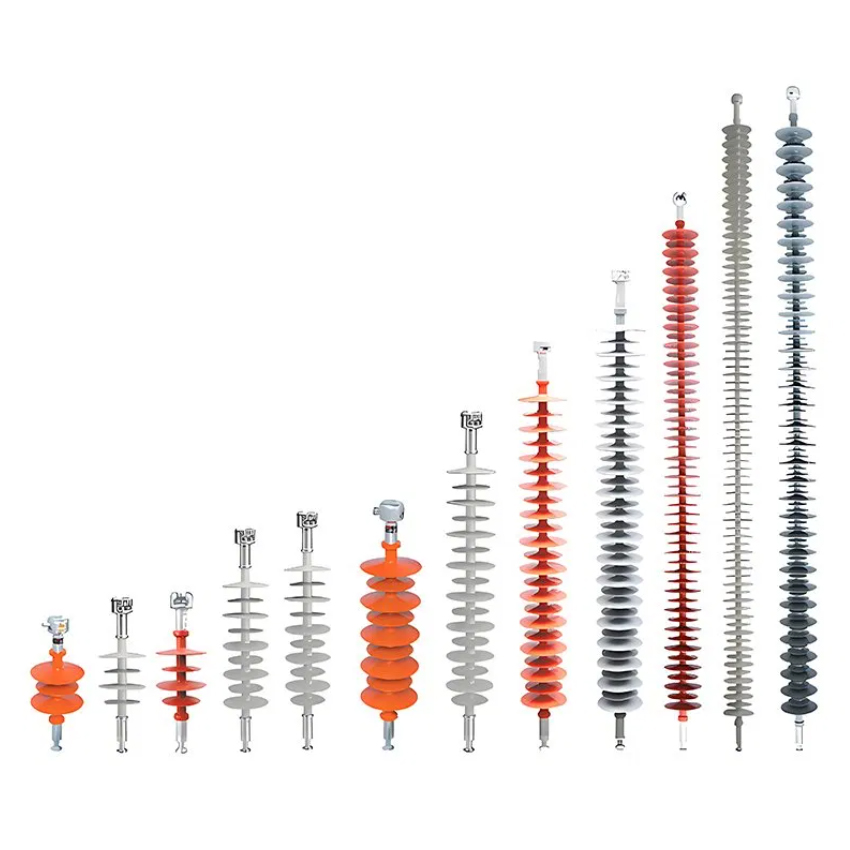

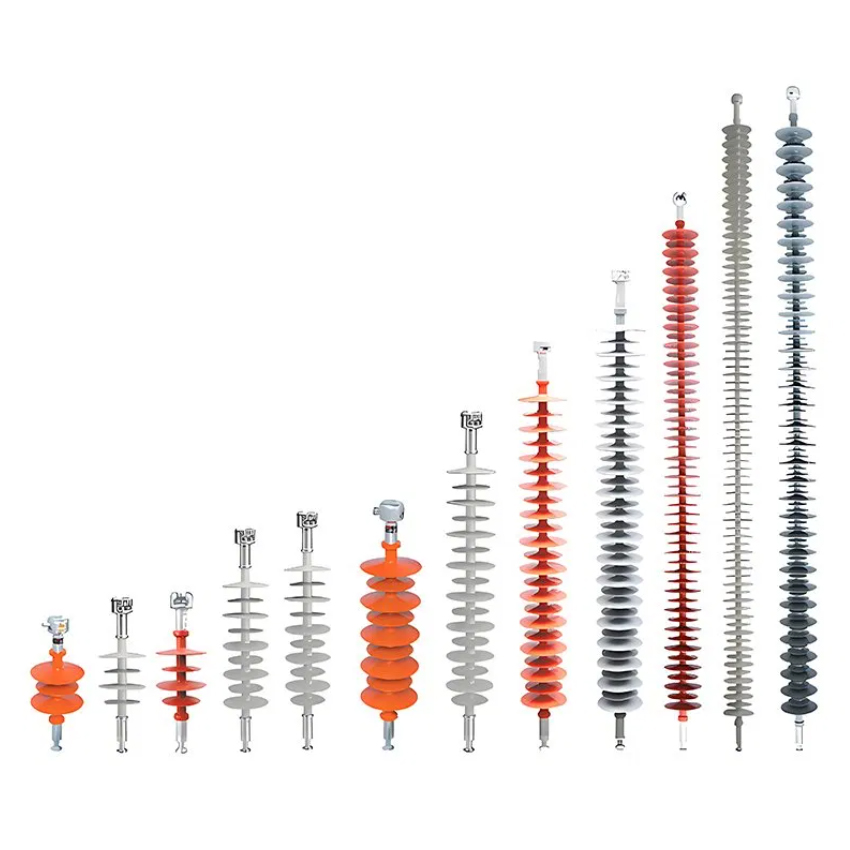

Durable Washer Production: Ideal for creating high-performance washers for both industrial and domestic use.

Reliable Sealing Solutions: Delivers superior compression and sealing for mechanical and fluid systems.

Effective Electrical Insulation: Perfect for electrical gaskets and washers, ensuring enhanced safety in electrical applications.

Versatile Industrial Components: Suitable for manufacturing sealing rings, cushioning pads, and other essential parts.

Durable Washer Production: Ideal for creating high-performance washers for both industrial and domestic use.

Reliable Sealing Solutions: Delivers superior compression and sealing for mechanical and fluid systems.

Effective Electrical Insulation: Perfect for electrical gaskets and washers, ensuring enhanced safety in electrical applications.

Versatile Industrial Components: Suitable for manufacturing sealing rings, cushioning pads, and other essential parts.

Mixing with Curing Agents: Combine silicone rubber with curing agents at a 1.3% ratio for optimal results.

Vulcanization Process: Heat the material to 130°C for 5 minutes under 15 MPa pressure for curing.

Cooling After Vulcanization: Allow the product to cool properly to retain elasticity and long-lasting durability.

Mixing with Curing Agents: Combine silicone rubber with curing agents at a 1.3% ratio for optimal results.

Vulcanization Process: Heat the material to 130°C for 5 minutes under 15 MPa pressure for curing.

Cooling After Vulcanization: Allow the product to cool properly to retain elasticity and long-lasting durability.

Q: Is this silicone rubber suitable for washer production?

A: Yes, it is specially designed for washers, providing excellent sealing and compression properties.

Q: Can the hardness be customized?

A: Yes, the rubber is available in Shore A hardness from 50 to 80 for diverse uses.

Q: What certifications does this material have?

A: It complies with ROHS, REACH, and FDA standards for both environmental and consumer safety.

Q: What are the key benefits for washer applications?

A: The material offers low compression set, high tear strength, and excellent durability for washers.

Q: How durable is this silicone rubber under stress?

A: It is highly durable, maintaining performance under continuous pressure and mechanical stress.

Q: Is this silicone rubber suitable for washer production?

A: Yes, it is specially designed for washers, providing excellent sealing and compression properties.

Q: Can the hardness be customized?

A: Yes, the rubber is available in Shore A hardness from 50 to 80 for diverse uses.

Q: What certifications does this material have?

A: It complies with ROHS, REACH, and FDA standards for both environmental and consumer safety.

Q: What are the key benefits for washer applications?

A: The material offers low compression set, high tear strength, and excellent durability for washers.

Q: How durable is this silicone rubber under stress?

A: It is highly durable, maintaining performance under continuous pressure and mechanical stress.